Founder Ansan P Sam aimed to enhance the efficiency of workers engaged in cardamom farming and boost productivity. To achieve this, he decided to design efficient machines as a viable solution. His initiative was undertaken as part of his ELDP course, organized by the Indian Institute of Management Kozhikode LIVE and powered by Moonpreneur.

Attend our in-person Robotics & Math

Attend our in-person Robotics & Math

AIM

Develop an efficient machine for getting high profit and reducing the effort of workers on washing

cardamom. Conventional machine or process fails to lessen the effort of the workers and obtain

continues process.

OBJECTIVES

1. Systematic review of studies evaluating the effectiveness of Cardamom Cleaning Machine.

2. To build a Cardamom Cleaning Machine to improve the quality of cardamom after cleaning.

3. To make the cleaning process continuous with faster rate and less effort.

4. Outcome measures were good quality and less damaged cardamom.

5. Zero crushed cardamom during the cleaning process

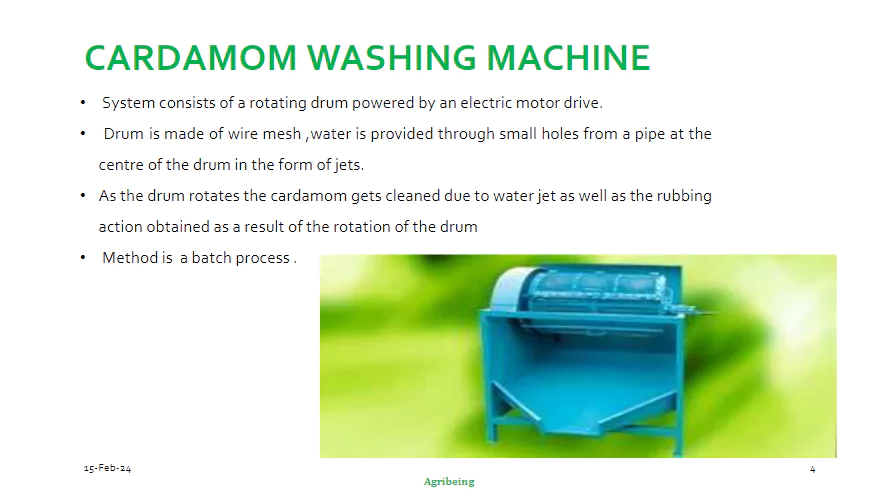

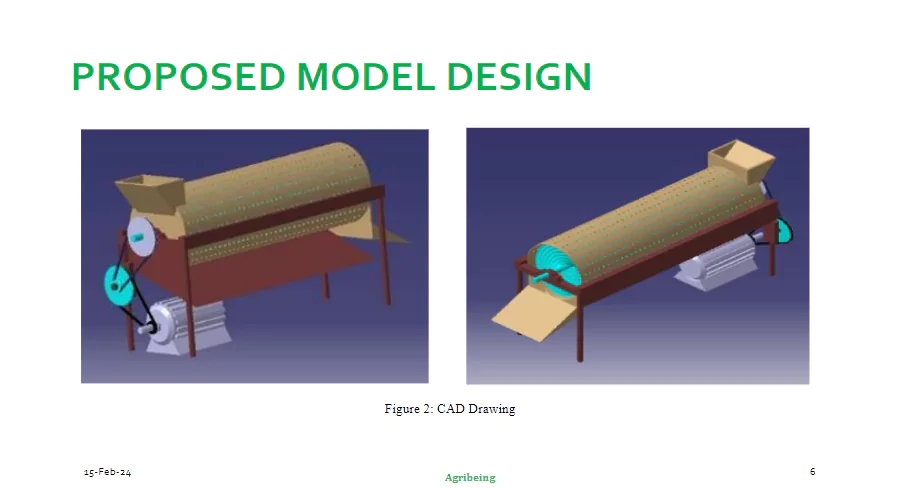

WORKING

• Machine there are mainly 4 parts Auger, Outer drum, driving mechanism, water feeding mechanism.

• Auger helps in the forward motion and it also support the cleaning action since the auger is made up of brushes.

• The auger is rotated inside an outer drum which provide the support. The outer drum have small holes in it for the intake of water. One of the side of outer drum have a hopper for the intake of cardamom and the other end is also opened for taking out the cleaned cardamom.

• The auger is rotated with help of a half HP motor whose 1440rpm is reduced to 53rmp with the help of reduction pulley.

• Water for the washing process is given through the holes provided in the outer drum.

Product/Services Detail

AIM

Develop an efficient machine for getting high profit and reducing the effort of workers on washing

cardamom. Conventional machine or process fails to lessen the effort of the workers and obtain

continues process.

OBJECTIVES

1. Systematic review of studies evaluating the effectiveness of Cardamom Cleaning Machine.

2. To build a Cardamom Cleaning Machine to improve the quality of cardamom after cleaning.

3. To make the cleaning process continuous with faster rate and less effort.

4. Outcome measures were good quality and less damaged cardamom.

5. Zero crushed cardamom during the cleaning process

WORKING

• Machine there are mainly 4 parts Auger, Outer drum, driving mechanism, water feeding mechanism.

• Auger helps in the forward motion and it also support the cleaning action since the auger is made up of brushes.

• The auger is rotated inside an outer drum which provide the support. The outer drum have small holes in it for the intake of water. One of the side of outer drum have a hopper for the intake of cardamom and the other end is also opened for taking out the cleaned cardamom.

• The auger is rotated with help of a half HP motor whose 1440rpm is reduced to 53rmp with the help of reduction pulley.

• Water for the washing process is given through the holes provided in the outer drum.

Product/Services Detail

CONCLUSION

1. Cardamom Cleaning Machine makes the process of cardamom cleaning continuous, fast and

easy.

2. It will improve the quality of cardamom coming out from the machine. This machine will

completely replace the existing machine.

3. Since here we are using less force on the cardamom, the chances to crush it is reduced to

minimum or zero.

4. Major drawback of the existing machine is that the process is not continuous which is solved by

the CCM.

5. Here the force needed for the cleaning action is minimum since the amount of cardamom inside

the machine at an instant is very less compared to the existing one.

6. Device has the potential to generate better quality output.

7. The advantages of the CCM is easy transport, moderately priced, less driving force, and minimum

water usage.

CONCLUSION

1. Cardamom Cleaning Machine makes the process of cardamom cleaning continuous, fast and

easy.

2. It will improve the quality of cardamom coming out from the machine. This machine will

completely replace the existing machine.

3. Since here we are using less force on the cardamom, the chances to crush it is reduced to

minimum or zero.

4. Major drawback of the existing machine is that the process is not continuous which is solved by

the CCM.

5. Here the force needed for the cleaning action is minimum since the amount of cardamom inside

the machine at an instant is very less compared to the existing one.

6. Device has the potential to generate better quality output.

7. The advantages of the CCM is easy transport, moderately priced, less driving force, and minimum

water usage.